مسكن

>

cement production line layout

مسكن

>

cement production line layout

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

cement production line layout

5 Main Types of Plant Layout | Industries

Product Layout: It is also known as line (type) layout. It implies that various operations on raw material are performed in a sequence and the machines are placed along the product flow line,, machines are arranged in the sequence in which the raw material will be operated upon. This type of layout is preferred for continuous production,, involving a continuous flow of inprocess Production process : In assembly line industries, product layout is better. In job order or intermittent manufacturing on the other hand, process layout is desirable. 4. Type of machinery: General purpose machines are often arranged as per process layout while special purpose machines are arranged according to product layout. 5. Repairs and maintenance : Machines should be so arranged that Plant layout ppt by me SlideShare4 In the calculation of the production loss of the complete cement production line and clinker production line, the production loss of coal should be calculated at %, and the production loss of other materials should be calculated at %. The production loss of all materials in the cement grinding station shall be calculated at %.Cement factory production line production

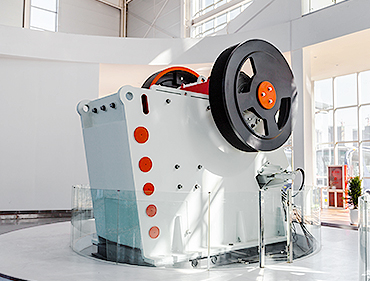

Cement Production Line_

Cement Production Line___。Rotary Kiln Cement Plant Manufacturing Process 1. Crushing Proportioning : In cement manufacturi Rotary Kiln Cement Plant Manufacturing Process 1. Crushing Proportioning : In cement manufacturing process the main raw material is limestone grinding, which is crushed and transported to the preblending stockpile by means of Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process. The two processes are How Cement Is Made Portland Cement For a more detailed account of the cement production process, see the Understanding Cement book. View of a cement kiln (the long nearlyhorizontal cylinder) and preheater tower. (Picture courtesy Castle Cement.) Summary of production process. Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then Cement manufacturing components of a

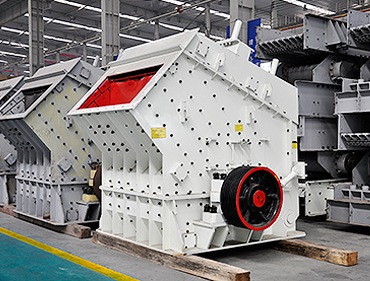

China Cement Production Line Cement Plant

Cement Production Line Cement Plant picture from Shanghai Clirik Machinery Co., Ltd. view photo of Cement Machinery, Cement Plant, Cement Production LineA cement mill (or finish mill in North American usage) Ball Mill Layout. A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of high Cement mill Wikipedia· Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide. High temperature of kiln Cement Manufacturing Process | Phases | Flow

Cement Plant Process Diagram Buy Cement

Cement Plant Process Diagram, Find Complete Details about Cement Plant Process Diagram,Cement Plant Process Diagram,Cement Production Line,Cement Production Line Layout from Cement Making Machinery Supplier or ManufacturerZhengzhou Huanqiu Heavy Industries Ltd.The production line should ideally be designed to eliminate waste in material flows, inventory handling and management. In process layout, the work stations and machinery are not arranged according to a particular production sequence. Instead, there is an assembly of similar operations or similar machinery in each department (for example, a drill department, a paint department, etc.) It is Process layout WikipediaTypical Process Layout for Cement Production. Home » Industries » Cement Industry Chains » Typical Process Layout for Cement Production. Have questions or need a quote? Get in touch with the team today. Get in Touch. SUBSCRIBE TO OUR NEWSLETTER. Email * I agree to the privacy policy and terms. ABOUT OUR COMPANY. The John King Company was established in Leeds, England in Typical Process Layout for Cement Production |

Cement plant design and production line

layout of cement plant in ethiopia. At present it has completed over 60 new dryprocess cement clinker production lines of various sizes tons day more than 10 pure low temperature waste heat power generation projects for cement clinker production lines and over 20 cement grinding station projects We are a professional Cement plant design consultantCementspecific solutions Solutions for a sustainable cement production Costefficient production and a simultaneous emissions reduction can only be achieved by using components that are perfectly adapted to one another. In its SICEMENT product family, Siemens links automation, drive, and power supply systems to form one overall solution. The Cement | Marketspecific Solutions | GlobalCement Production Line China Lime Production Line supplier. Construction waste crushing equipment Low Speed Driving Cement Production Line Automatic Welding Shell For Chemical Field Yz4030 Gypsum Rotary Kiln Plant Continuous Dry Process Calcination Kiln 3000tpd Cement Production Line Yz4060 Dry . Get Price ; 8 Ways to Reduce Manufacturing Waste Fishbowl Blog. Jan 31 2018 · Edinburgh cement production line processing

Fiber Cement Production LineChina Fiber

China Fiber Cement Production Line Select 2020 Fiber Cement Production Line products from verified China Fiber Cement Production Line manufacturers, suppliers on We can provide EPC turnkey project for complete cement plant and have successfully finished the construction of cement production lines of 4000t/d, 3000t/d, 2500t/d, 1500t/d, 600t/d, 300t/d and 150t/d GMG design cement plant according to layout diagram and process flow chart for cement industry in Zambia, Pakistan, Ghana, USA, Russia, Brazil, North Korea, Libya, UAE, Bangladesh.Cement Manufacturing Line Buy Cement